Stretching Sustainability: The Theoretical Process Of Recycling Spandex-Based Fabrics

Share Post

Spandex is a synthetic polymer made from a long chain of segmented polyurethanes. The elasticity of Spandex results from the soft, amorphous segments that stretch and the hard, crystalline segments that return it to its original shape. These unique properties make it indispensable in garments requiring flexibility. However, these same properties complicate the recycling process. The high elasticity interferes with mechanical recycling processes. Its thermal sensitivity restricts melting-based processes, and its common use in blends with other fibers adds layers of complexity.

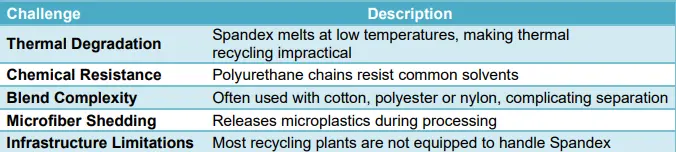

Recycling Spandex-based fabrics is problematic due to both physical and chemical limitations. Spandex degrades at high temperatures, limiting traditional thermal recycling. The polymer chains resist breaking down via most conventional chemical means. During washing and processing, Spandex can release synthetic microfibers, and its usage with cotton or polyester complicates separation. Moreover, most global recycling plants are not equipped to handle Spandex.

Traditional recycling methods such as mechanical recycling, which involves shredding and melting fabrics to be respun into yarn, are not viable for Spandex. The material melts at a lower temperature than other fibers, causing inconsistencies and degraded elastic recovery. Chemical recycling attempts to break down polymers into monomers or base chemicals but faces limitations because polyurethane in Spandex resists most solvents and requires hazardous chemicals or high energy input. These processes are not feasible on an industrial scale without innovation.

Advancements in polymer science and textile engineering are opening new doors. Emerging solutions include selective dissolution, enzymatic degradation, supercritical CO2 separation, and microwave-assisted pyrolysis. Selective dissolution uses highly specific solvents to dissolve one component (e.g., polyester) from a blended fabric, leaving behind Spandex. Enzymatic degradation involves engineered enzymes that can break down polyurethanes in a bio-based, environmentally friendly process, although it is still under lab-scale development. Supercritical CO2 technology utilizes supercritical fluids to swell polymers and extract individual components without water or solvents, though the equipment costs are high. Microwave-assisted pyrolysis rapidly breaks down Spandex components into reusable oils and gases, offering precise heat targeting and fast processing time, but is still in the research stage.

To support these processes, new machinery is being developed. Multi-fiber separation units use advanced sensors and automated sorting systems to identify and isolate Spandex blends from waste streams. Twin-screw reactive extruders allow for in-situ chemical reactions during melting, controlling heat application specific to Spandex and stabilizing degraded polymers. BioReactor chambers offer a controlled environment for enzymatic recycling using engineered bacteria. Closed-loop CO2 machines recycle CO2 within the system, ideal for blended fabric delamination. Automated fiber ID and laser cutting tools precisely target materials, reducing waste and minimizing energy input. Challenges in Recycling Spandex-Based Fabrics: Several pilot projects and textile innovators are experimenting with Spandex recycling. Worn Again Technologies (UK) is working on polymer separation techniques to isolate Spandex. Circ (US) specializes in hydrothermal processing to recycle polycotton and elastane. Carbios (France) is developing enzymatic recycling for synthetic fibers. These initiatives signal a shift toward a circular textile economy.

To support these processes, new machinery is being developed. Multi-fiber separation units use advanced sensors and automated sorting systems to identify and isolate Spandex blends from waste streams. Twin-screw reactive extruders allow for in-situ chemical reactions during melting, controlling heat application specific to Spandex and stabilizing degraded polymers. BioReactor chambers offer a controlled environment for enzymatic recycling using engineered bacteria. Closed-loop CO2 machines recycle CO2 within the system, ideal for blended fabric delamination. Automated fiber ID and laser cutting tools precisely target materials, reducing waste and minimizing energy input. Challenges in Recycling Spandex-Based Fabrics: Several pilot projects and textile innovators are experimenting with Spandex recycling. Worn Again Technologies (UK) is working on polymer separation techniques to isolate Spandex. Circ (US) specializes in hydrothermal processing to recycle polycotton and elastane. Carbios (France) is developing enzymatic recycling for synthetic fibers. These initiatives signal a shift toward a circular textile economy.

Recycling Spandex-based fabrics has both environmental and economic implications. It reduces synthetic waste in oceans, cuts down microplastic shedding, and promotes circular fashion systems. Economically, while initial costs are high, long-term benefits and subsidies from governments and brands make it viable. Green-conscious consumerism is also driving demand for sustainable materials. Governments can play a pivotal role by standardizing recycling labels, offering incentives for machinery upgrades, mandating textile take-back schemes from brands, and introducing Extended Producer Responsibility (EPR) for Spandex-heavy products. This support can accelerate the transition toward a circular economy.

The road to large-scale Spandex recycling is complex but not impossible. With increasing pressure from global sustainability frameworks like the UN’s SDGs and EU’s Green Deal, innovation in Spandex recycling must continue. Future projections include hybrid mechanicalchemical recycling systems, smart wearable sensors that track fiber content for easier recycling, modular recycling hubs in urban centers, and fully bio-based biodegradable Spandex alternatives.

Recycling Spandex-based fabrics is one of the final frontiers of sustainable textile innovation. While the material’s properties make it indispensable in modern fashion, they also make it incredibly difficult to recycle using conventional systems. However, theoretical models, emerging technologies, and new machinery are charting a future where even the most complex fiber blends can re-enter the production cycle. With crosssector collaboration linking machinery developers, recyclers, academic researchers, brands, and policymakers the dream of circular Spandex recycling can soon become a widespread reality. This journey is not only about reducing waste but reimagining how textiles are made, used and reused. It is about crafting a fabric of sustainability that stretches as far as our innovations allow.

11:31 AM, Nov 12

Other Related Topics

.webp)

.webp)

.webp)