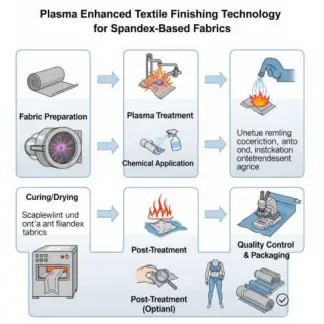

Plasma Enhanced Finishing Technology For Spandex-Based Fabrics

Share Post

Plasma Enhanced Finishing Technology (PEFT) has emerged as a groundbreaking solution. This environmentally friendly, dry-finishing method offers precise surface modification without damaging the intrinsic elastic properties of spandex.

Finishing processes are critical in transforming raw fabric into a value-added product with desirable performance characteristics. For spandex-based textiles, the challenge lies in achieving enhancements such as better dyeability, softness, moisture-wicking, and antimicrobial protection without compromising elasticity or causing degradation. As sustainability becomes a central concern, there’s growing demand for cleaner, greener finishing technologies.

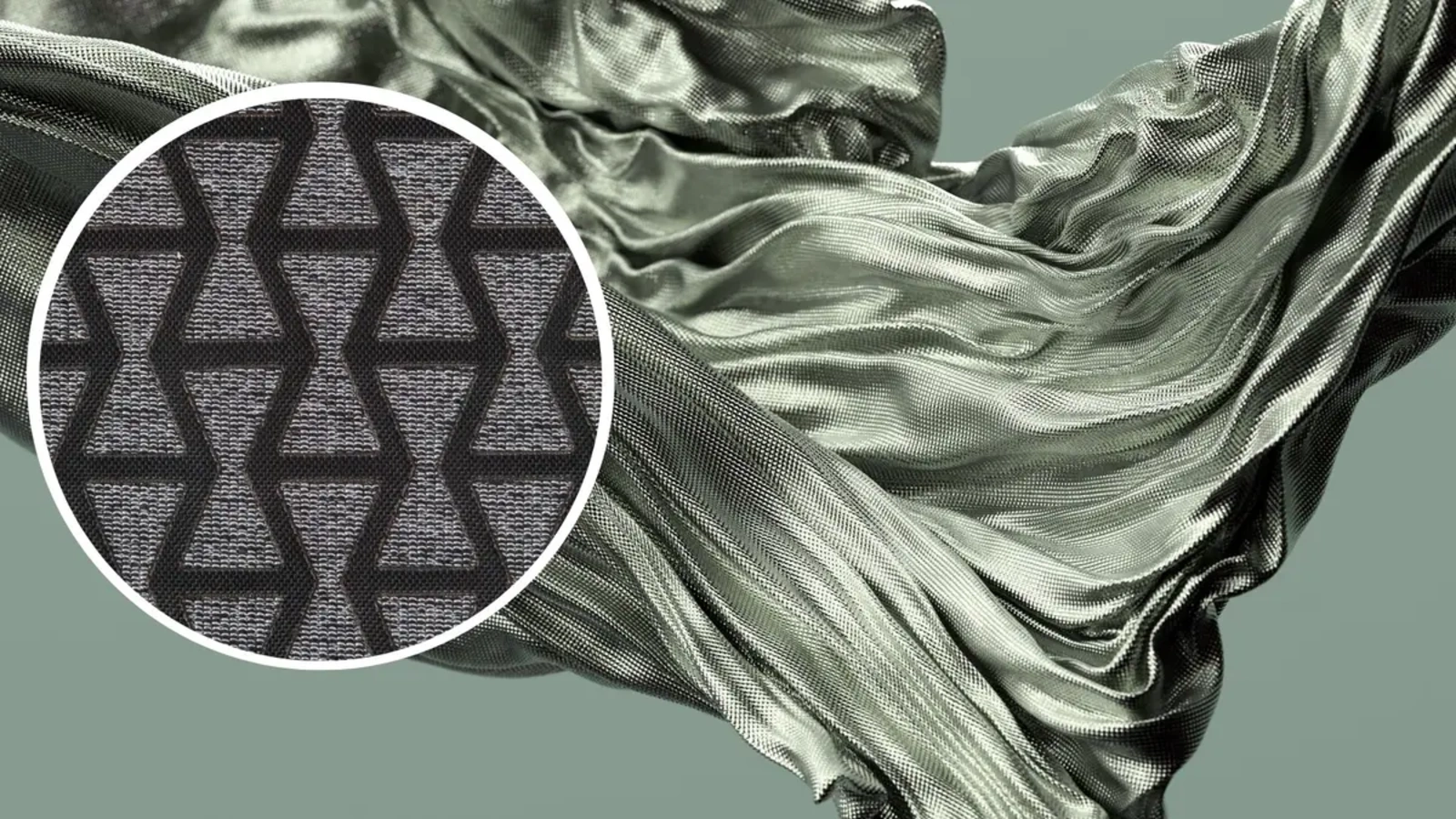

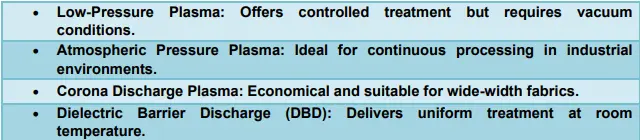

Plasma finishing is a surface engineering process that modifies textile surfaces using ionized gases under atmospheric or low-pressure conditions. This non- thermal, solvent-free method alters only the surface layer of the fabric, introducing new functionalities while maintaining its core structural integrity. It is particularly effective on synthetic and blended fabrics, including spandex blends. There are several types of plasma systems used in textile finishing:

Among these, APP and DBD are most suited for treating spandex fabrics due to their uniformity and compatibility with continuous processing.

Plasma is generated when an electrical field imparts enough energy to a gas commonly oxygen, nitrogen or argon to strip electrons from its atoms and molecules. This ionization transforms the gas into a dynamic cocktail of free electrons, positively charged ions, reactive radicals and ultraviolet photons. When this energized mixture encounters a textile surface, it triggers a cascade of chemical and physical interactions without relying on water or added chemical reagents.

Through plasma treatment, the fabric undergoes three principal modifications. First, etching occurs as high-energy species gently ablate and remove weak boundary layers, dust and other surface contaminants, revealing a clean, fresh substrate. Next, activation takes place: reactive functional groups such as hydroxyl, carboxyl and amine moieties are grafted onto the fibers, dramatically increasing the surface’s chemical affinity. Finally, crosslinking is promoted, creating stable sites that facilitate the uniform attachment of coatings, dyes or other finishing agents. Together, these changes enhance wettability, adhesion and durability, all while minimizing environmental impact.

These surface changes increase surface energy, enabling better dye absorption, moisture management, and functional finishes. Applications of PEFT in Spandex Textiles:

Boosting Dye Affinity: Spandex typically resists dye penetration due to its low surface energy. Plasma treatment introduces polar functional groups, improving dye uptake and resulting in richer, more uniform coloration. This reduces dependency on harsh chemical auxiliaries.

Improving Moisture Wicking and Breathability: Plasma-treated spandex fabrics become more hydrophilic, enhancing their ability to wick away moisture from the skin. This is particularly beneficial in activewear and innerwear, where dryness and breathability are essential for wearer comfort.

Enabling Durable Antimicrobial Finishes: Through PEFT, antimicrobial agents such as silver nanoparticles or herbal extracts can be effectively bonded to the spandex surface. This provides long- lasting odor control and hygiene benefits without repeated chemical treatments. Adding UV and Stain Resistance: Plasma processes facilitate the grafting of UV-absorbing molecules, protecting skin from harmful radiation. Likewise, stain-resistant coatings can be more effectively applied, especially in lifestyle and outdoor garments.

Enhancing Coating Adhesion and Lamination: Plasma-treated spandex exhibits improved surface bonding, making it suitable for lamination with technical membranes or foams. This opens up applications in compression garments, sportswear, and orthopedic products.

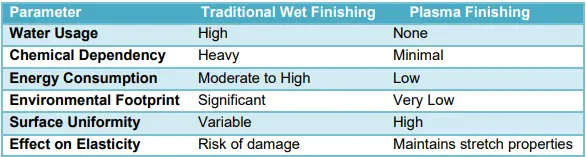

Comparing PEFT with Traditional Finishing Techniques

While Plasma Enhanced Finishing Technology (PEFT) offers numerous advantages, it also comes with certain limitations that must be considered. One of the primary challenges is the high initial investment required for equipment and setup, which can be a barrier for smaller manufacturers.

Additionally, PEFT impacts only the outermost surface layers of the fabric, limiting the depth of treatment. The process is also highly sensitive if over-applied, it may degrade the elasticity of fibers such as spandex. Moreover, achieving consistent and uniform treatment across wide-width fabrics poses a scalability issue, particularly in mass production settings. Despite these challenges, PEFT holds significant promise for the future of textiles, especially in the realm of smart and functional materials.

The technology enables the surface of spandex fabrics to be functionalized with conductive inks, nanosensors, and responsive coatings, opening avenues for applications in fitness tracking, posture- correcting garments, and wearable health monitors. When combined with eco-efficient chemical finishing techniques, PEFT can lead to hybrid methods that deliver multiple benefits such as durability, breathability, and specialized functionalities in a single, environmentally friendly process.

Importantly, PEFT also supports the vision of a circular textile economy. By drastically reducing the need for water and harsh chemicals, the technology aligns well with sustainability goals and environmental compliance standards. This resonates strongly with both industry regulations and the growing consumer demand for cleaner production practices. In this way, PEFT contributes to the development of responsible and forward-looking manufacturing approaches.

In essence, Plasma Enhanced Finishing Technology marks a transformative shift in how textile surfaces particularly spandex-based fabrics are treated. Its surface-specific, non-polluting, and precision- controlled approach makes it an ideal candidate for performance-oriented and sustainable textile development. While certain barriers like cost and scalability remain, ongoing research and increasing demand for eco-conscious innovations are steadily pushing PEFT toward broader adoption. For manufacturers, researchers, and environmental advocates alike, PEFT is not merely a new tool it represents the future of ethical and efficient textile finishing.

10:55 AM, Nov 12

Other Related Topics

.webp)