Global And Indian Nonwoven Industry Trends & India’s Strategic Growth With Btra Support

Share Post

Nonwoven fabrics, a unique class of textile materials, have dramatically transformed various industries since their rise in the mid-20th century. Originally developed using adhesives or heat to bond fibrous webs, nonwoven technology matured rapidly after World War II, evolving from basic technical applications like tea bags and filters into pivotal roles in hygiene, medical disposables, geotextiles, and technical consumer goods.

Nonwoven fabrics are composed of either staple fibers or continuous filaments bonded chemically, mechanically, or thermally to create flat, porous sheets. Unlike traditional woven textiles, nonwovens provide versatility, cost-effectiveness, and performance benefits, driving their adoption across a broad spectrum of applications.

Diverse Applications Spearheading Demand

Nonwoven materials serve an extraordinarily wide array of purposes. In the medical sector, they are critical in making isolation gowns, surgical drapes, masks, caps, gloves, wound dressings, and drug delivery systems, where breathability and sterilization compatibility are crucial.

In filtration, nonwovens are used in gasoline, oil, air filters including HEPA systems, water purification, pharmaceutical processes, and vacuum bags. Their unique porosity makes them indispensable in these areas.

Geotextiles utilize nonwoven fabrics for soil stabilization, erosion control, drainage, canal construction, landfill liners, and road underlayments, supporting sustainable infrastructure and environmental protection.

Further applications extend to hygiene products (diapers, feminine hygiene), carpet backing and composites, marine sail laminates, packaging requiring breathability, reusable shopping bags, insulation in appliances and automotive parts, upholstery padding, and disposable clothing. This vast usage underlines nonwovens’ essential role in daily life and industrial processes.

Current Market Trends: Growth Drivers and Innovation Hygiene and medical applications lead the current growth trajectory, driven by heightened demand for single-use disposables and protective equipment. This surge has intensified research and capacity expansion globally, especially post-pandemic.

Sustainability is at the forefront of development. Industry focus has shifted to recyclable feedstocks, bio-based Fibers, and energy-efficient production methods, including extensive use of recycled PET in spunbond and spunlace technologies.

Technological innovation is also a key catalyst. Meltblown capacity expansion, essential for filtration and PPE, and advanced texturing techniques for spunlace and composite laminates are transforming the nonwoven landscape. These technological advancements deliver higher-value functional textiles designed for automotive, geosynthetics, filtration, and construction markets.

Regional supply chains, especially in Asia and India, are adapting rapidly to post-pandemic realities. Reshoring and local capacity investment are becoming critical to supply resiliency and cost competitiveness.

Market Landscape: Global and India

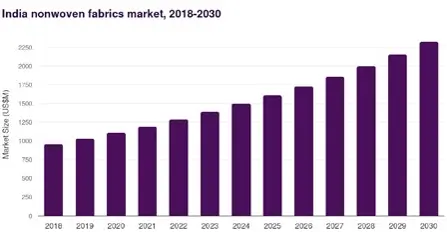

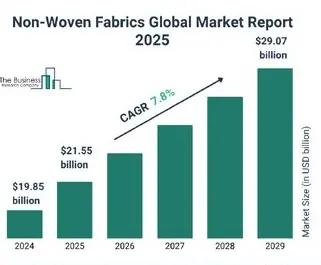

The global nonwoven market size was estimated at almost $20 billion in 2024, with projections to reach over $29 billion by 2029, growing at a compound annual growth rate (CAGR) of approximately 7.8%. This robust growth is fueled primarily by hygiene, medical, and technical textile segments.

India’s nonwoven sector mirrors this trajectory with a fast-growing market valued in the low billions USD as of 2024 and forecast to maintain mid to high single-digit CAGR through 2030. Rising domestic demand, coupled with new manufacturing plants and public investment interest, illustrates the sector’s vibrant outlook.

Indian manufacturers are actively adding capacity in spunbond, meltblown, and hygiene-related production lines. The entry of smaller nonwoven companies into public equity markets demonstrates investor confidence in the sector’s potential. Additionally, domestic efforts to localize meltblown and filtration production have drastically reduced India’s reliance on imports since the 2020 PPE demand surge.

The Bombay Textile Research Association (BTRA): India’s Supportive Backbone

The Bombay Textile Research Association (BTRA) plays a pivotal role in India’s nonwoven ecosystem by providing testing, research and development, and technical services to the textile and nonwoven sectors.

With advanced testing infrastructure capable of performing international standard-compliant evaluations, BTRA ensures that nonwoven products meet strict specifications, regulatory norms, and export readiness.

BTRA’s R&D efforts are multifaceted, ranging from developing flexible conductive polymeric materials to antibacterial and antiviral nonwovens for medical applications, thermal insulation fabrics, and customized geotextile solutions. Its pilot-scale facilities enable prototype development and product refinement, reinforcing quality and innovation in India’s nonwoven manufacturing.

Manufacturers benefit immensely from BTRA’s capabilities in product performance testing, chemical analysis, troubleshooting, and developmental assistance for specialized nonwoven constructions. Accreditation and a long-standing reputation make BTRA a trusted partner supporting India’s nonwoven companies in achieving regulatory compliance and penetrating export markets.

Looking Forward: Sustainability and Product Innovation Sustainability remains the key driver steering new product and process advancements in nonwovens. Developments in recyclable materials, durable nonwoven composites, and multifunctional textiles are set to define the next generation of high-value technical nonwovens.

The future promises nonwoven fabrics that transcend conventional types, integrating advanced functionalities tailored for critical applications in medical, automotive, environmental, and construction industries.

At Last

India’s nonwoven sector is witnessing an inflection point characterized by rapid market expansion, technological evolution, and sustainability imperatives. With global demand projected to accelerate, India is poised to become a significant player, supported by robust research institutions like BTRA and growing domestic manufacturing capabilities.

Stakeholders focusing on quality, innovation, and sustainability are likely to lead this transformative phase, making Indian nonwoven producers competitive forces in global markets by 2030 and beyond.

01:08 PM, Nov 12

.webp)

.webp)

.webp)

1.webp)